Brushed Vs Brushless Drills

Power tools are essentials not only for the professionals but also for several homeowners. Homeowners find it easier to have these tools at their disposal in times of need. Whether it’s for a DIY project or a professional endeavor, owning a powerful drill takes the project speed and efficiency to the next level.

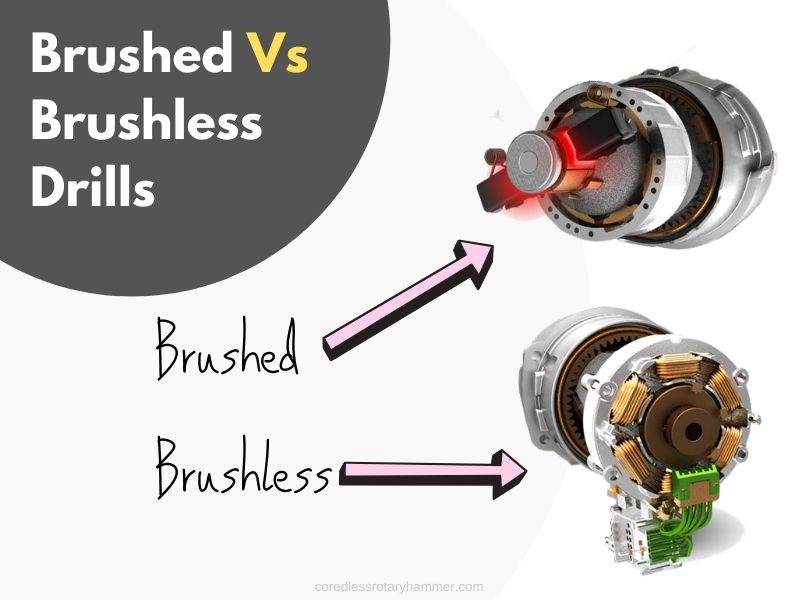

There are a lot of great drills in the market, and the two variants of it being the brushed motor drills, and the brushless motors drills.

For a non- professional, it is common to wonder the price difference between the brushless and its counterpart when both products fulfill the same purpose. Without the proper context, you may choose one over the other for no apparent reason. But the wise thing to do is to assess the differences between the two types. It will make it easier to determine which is the right choice for you, rather than choosing one on a whim.

All motors work on the similar principle of converting electrical energy into power or mechanical energy. The first commercially important application of electric power to driving mechanical energy was Brushed motors. Brushless drills came around in the 1960s, and are gaining popularity at a substantial pace in recent years.

Before venturing into buying a drill, you should know the following key differences between the two.

Difference between the brushless drill and brushed drill

The principal difference between brushed and brushless motors is in their structuring. A brushed motor has small metal brushes of carbon along with magnets. On the other hand, a brushless motor has an electronic circuit board and sensors. Here are some more points, you can look into to decide which motor you should go with, for your projects.

Hall Effect sensor:

Brushless motors have a sensor that automatically adjusts its speed, torque, and power, based on the requirements of the project at hand. That means, if the resistance from the material is little, the motor will adjust to a lower speed/power range, and if it senses higher resistance from the object, it will adjust the speed and power accordingly. In the case of a brushed motor, the power and speed are going to be the same, no matter what the resistance from the object is. In this regard, brushless motors provide a higher degree of control to the users.

Battery life:

Since the brushed motor has brushes, it generates a lot more grinding than the brushless motor. More friction means more heat, which results in a lot of energy loss during this. Thus, there is not much scope of longer battery life in the brushed motor. On the other hand, the absence of brushes in the brushless drills solves this problem, making it energy efficient.

Size:

Since a brushless drill has fewer parts as compared to the brushed ones, it is compact in size, and lighter in weight as well. It is almost 25% more compact than the brushed one, making it a better option for tighter work areas.

Maintenance:

You need to replace the brushes in the brushed motors after a short while. It is mostly due to the wear and tears from the heat. Although the replacement is not hard to do, it is necessary after every 50-60 hours of use.

On the other hand, a brushless drill does not have any brushes, so no such procedure is required. However, if a brushless drill stops working, you might have to replace it altogether. A brushed motor’s maintenance is mostly related to its brushes.

Also, because of heat generation, a brushed drill requires air vents for it to cool off. These air vents can lead to dust and debris issues in the motor compartment. In contrast to this, a brushless motor does not need air vents. The absence of brushes and friction in the brushless motor also creates lesser noise, making it more suitable for use.

Durability:

The friction issue in the brushed motor results in more wear and tear and the life of these motors are, generally speaking, less than a brushless motor.

Why does a brushless drill have an extra cost?

The advantages that a brushless drill has over a brushed one are many. However, buyers are a bit hesitant when it comes to the pricing of a brushless drill. The extra cost for a brushless drill is due to its complex circuitry, and better functioning of the motor.

These drills generally use the high-performance lithium-ion batteries. Since these batteries are smaller and lighter in weight and are also more efficient, the overall cost of this brushless drill is more than the brushed models. Brushless drill is also more efficient, thanks to its sensor, which is absent from the brushed models.

The brushless drills are quickly replacing the brushed ones, but there is still a market for the brushed models. There is an apparent price difference between the two, however, the replacement brushes usually level out the price difference in time. So, it is up to you to decide which is the suitable one for you.

Conclusion

Now that we have done a thorough analysis of the brushless drills against the brushed ones, it will be easier for you to choose, based on the kind of work you need to do. Is it a one-time thing, or continuous work? Do you need a drill for a professional project or just for general use? All these questions and more need to be answered before you make a difference.

Both drills serve a similar purpose, but a lot depends on what kind of work do you need to do. Moreover, the factor of durability is also there when you’re thinking of making a purchase. If you need a drill that is easy on your budget, and for short-term purposes, then you should go for a brushed one without a second thought. However, if you want to make a long term and professional investment, then the cost of a brushless drill should not be a factor since the advantages it offers are numerous.